In vapour absorption system the refrigerant is absorbed on leaving the evaporator, the absorbing medium being a solid or liquid. In order that the sequence of events should be continuous it is necessary for the refrigerant to be separated from the absorbent and subsequently condensed before being returned to the evaporator. The separation is accomplished by the application of direct heat in a generator‘. The solubility of the refrigerant and absorbent must be suitable and the plant which uses ammonia as the refrigerant and water as absorbent will be described.

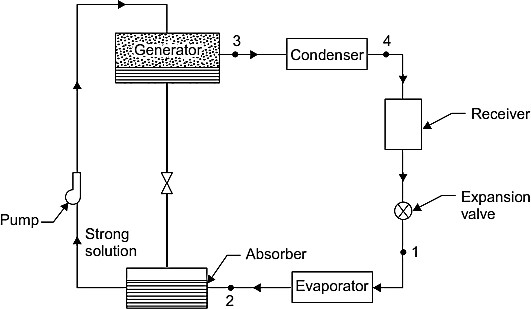

Simple Vapour Absorption System

Refer Fig. 1 for a simple absorption system. The solubility of ammonia in water at low temperatures and pressures is higher than it is at higher temperatures and pressures. The Ammonia vapour leaving the evaporator at point 2 is readily absorbed in the low temperature hot solution in the absorber. This process is accompanied by the rejection of heat. The ammonia in water solution is pumped to the higher pressure and is heated in the generator. Due to reduced solubility of ammonia in water at the higher pressure and temperature, the vapour is removed from the solution. The vapour then passes to the condenser and the weakened ammonia in water solution is returned to the absorber.

Fig. 1 Simple vapour absorption system

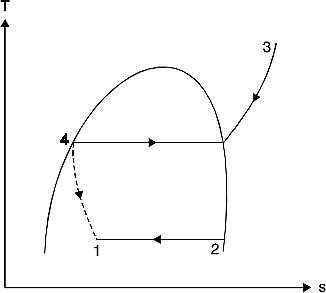

Fig. 1. (b) Simple vapour absorption system—T-s diagram

In this system the work done on compression is less than in vapour compression cycle (since pumping a liquid requires much less work than compressing a vapour between the same pressures) but a heat input to the generator is required. The heat may be supplied by any convenient form e.g. steam or gas heating.

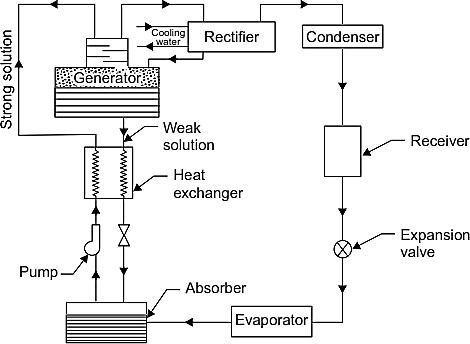

Practical Vapour Absorption System

Refer Fig. 2. Although a simple vapour absorption system can provide refrigeration yet its operating efficiency is low. The following accessories are fitted to make the system more practical and improve the performance and working of the plant.

- Heat 2. Analyzer. 3. Rectifier.

- Heat A heat exchanger is located between the generator and the absorber.

The strong solution which is pumped from the absorber to the generator must be heated; and the weak solution from the generator to the absorber must be cooled. This is accomplished by a heat exchanger and consequently cost of heating the generator and cost of cooling the absorber are reduced.

- An analyzer consists of a series of trays mounted above the generator. Its main function is to remove partly some of the unwanted water particles associated with ammonia vapour going to condenser. If these water vapours are permitted to enter condenser they may enter the expansion valve and freeze; as a result the pipe line may get choked.

Fig. 2 Practical Vapour Absorption System

- A rectifier is a water-cooled heat exchanger which condenses water vapour and some ammonia and sends back to the generator. Thus final reduction or elimination of the percentage of water vapour takes place in a rectifier.

The co-efficient of performance (C.O.P.) of this system is given by :

![]()

COMPARISON BETWEEN VAPOUR COMPRESSION AND VAPOUR ABSORPTION SYSTEMS

|

S. No. |

Particulars |

Vapour compression System |

Vapour absorption system |

| 1 | Type of energy supplied | Mechanical-a high grade Energy | Mainly heat-a low grade energy |

| 2 | Energy supply | Low | High |

| 3 | Wear and tear | More | Less |

| 4 | Performance at Part loads. | Poor | System not affected by variationsloads |

|

5 |

Suitability |

Used where high grade mechanical energy is available |

Can also be used at remote places as it can work even with a simple kerosene lamp (of course in small capacities) |

| 6 | Charging of refrigerant | Simple | Difficult |

|

7 |

Leakage of refrigerant |

More chances |

No chance as there is no compressor or any reciprocating component to cause leakage. |

|

8 |

Damage |

Liquid traces in suction line may damage the compressor |

Liquid traces of refrigerant present in piping at the exit ofevaporator constitute no danger. |

See also:

Vapour Compression Refrigeration