Condensers and evaporators are basically heat exchangers in which the refrigerant undergoes a phase change. In condensers the refrigerant vapour condenses by rejecting heat to an external fluid, which acts as a heat sink. In a typical refrigerant condenser, the refrigerant enters the condenser in a superheated state. It is first de-superheated and then condensed by rejecting heat to an external medium.

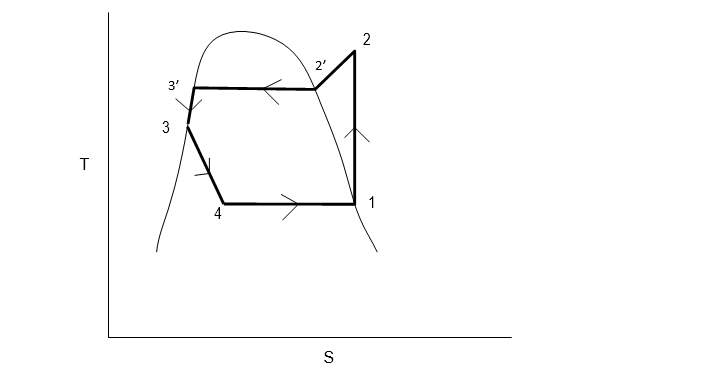

The refrigerant may leave the condenser as a saturated or a sub-cooled liquid, depending upon the temperature of the external medium and design of the condenser. Figure 22.1 shows the variation of refrigeration cycle on T-s diagram. In the figure, the heat rejection process is represented by 2-2’-3’-3. It can be seen that process 2-2’ is a de-superheating process, during which the refrigerant is cooled from a temperature T2 to the saturation temperature corresponding condensing pressure, T. Process 2’-3’ is the condensation process, during which the 2’ temperature of the refrigerant remains constant as it undergoes a phase change process. Process 3’-3 is a sub cooling process, during which the refrigerant temperature drops from T3’ to T3.

Classification of condensers:

Based on the external fluid, condensers can be classified as:

- Air cooled condensers

- Water cooled condensers, and

- Evaporative condensers

-

Air-cooled condensers:

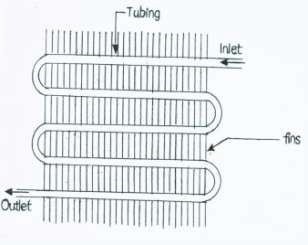

In air-cooled condensers air is the external fluid, i.e., the refrigerant rejects heat to air flowing over the condenser. it consists of steel or copper tubing through which refrigerant flows. Copper tubes are generally preferred due to its good heat transfer ability. Steel tubes used for ammonia refrigerant system. The tubes are provided with plate type fins to increase the surface area for heat transfer. The fins are made of aluminium. The air cooled condenser may have tubes up to 6 or 7 rows. More than 8 rows of tubing are not efficient because air temperature will get too close to the condenser temperature and heat absorption rate of air decreases. Air-cooled condensers can be further classified into natural convection type or forced convection type.

Natural convection type:

In natural convection type, heat transfer from the condenser is done by natural convection. As the air comes in contact with the warm condenser tubes, it absorbs heat from the refrigerant and temperature of air increases. The warm air got lighter and rises up taking away heat. The cold air from the surrounding takes the place to take away the heat from the condenser. The rate of heat transfer in natural convention type condenser is low.

Forced convection type:

In forced convection type condensers, the circulation of air over the condenser surface is maintained by using a fan or a blower. Forced convection type condensers are commonly used in window air conditioners, water coolers and packaged air conditioning plants. These are either chassis mounted or remote mounted. In chassis mounted type, the compressor, induction motor, condenser with condenser fan, accumulator, HP/LP cut- out switch and pressure gauges are mounted on a single chassis. It is called condensing unit of rated capacity. The remote mounted type, is either vertical or roof mounted horizontal type. They can be located either inside or outside the building. This system is used for capacity above 10 tonnes. For above 125 tonnes two or more condensers are used.

-

Water Cooled Condensers:

In water cooled condensers water is the external fluid. These are commonly used in commercial and industrial application. The water cooled condensers uses either of the following two water systems:

- Waste water system, 2. Re-circulated water system.

In waste water system, the water circulated in the condenser is discharged into sewer. This system is used where large quantities of waste water are available. In re-circulated water system, the same water circulated on condenser again and again after cooling. This system requires some water cooling system such as cooling tower or spray ponds. The warm water from the condenser is passed through cooling tower/spray pond, cooled there by self evaporation and then re-circulated in condenser. Additional make up water is required to replace the water that evaporates from the cooling tower.

Water cooled condensers can be further classified into:

- Double pipe or tube-in-tube type

- Shell-and-coil type

- Shell-and-tube type

(a) Double Pipe or tube-in-tube type:

Double pipe condensers are normally used up to 10 TR capacities. In these condensers the cold water flows through the inner tube, while the refrigerant enters at the top. The water absorbs the heat from the refrigerant and liquid refrigerant flows at the bottom. The refrigerant in the tubes rejects a part of its heat to the surroundings by free convection and radiation. The water in this type of system may flow in either direction. If the water flows in the same direction of refrigerant then it is called parallel flow system, when the water flow is opposite to the refrigerant then called counter flow system. In parallel flow system the temperature difference will be maximum at the inlet side and will be minimum at outlet side. I.e. the heat transfer rate decrease as it passes through the condenser. Thus, counter flow condenser is preferred in type of water-cooled condenser.

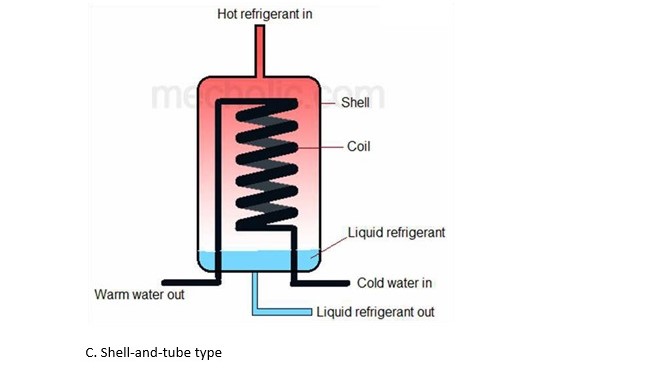

(b) Shell-and-coil type

The refrigerant flows through the shell and water flows through multiple coils. In smaller capacity condensers, refrigerant flows through coils while water flows through the shell. These type condensers may be either vertical or horizontal. The hot vapour refrigerant enters at the top of the shell and surrounds the water coil. The vapour condenses when it comes in contact with coil with cooling water supply and collects at the bottom of the shell. Counter flow water system is mostly preferred as it is more efficient than parallel flow water system. The coil inside the shell is allowed to expand and contract with temperature rise and fall. This spring action coil helps it to withstand temperature strain.

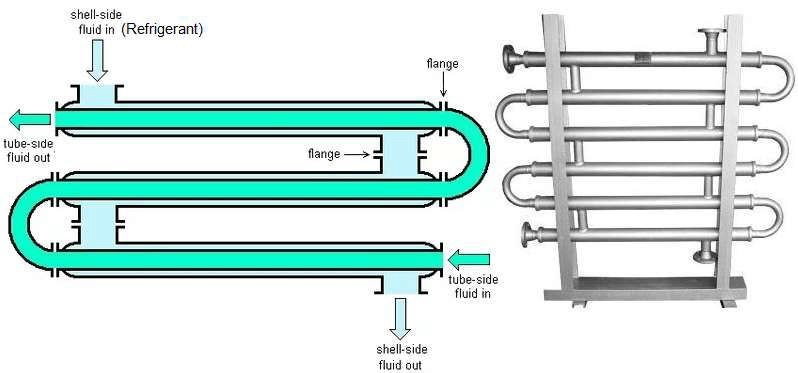

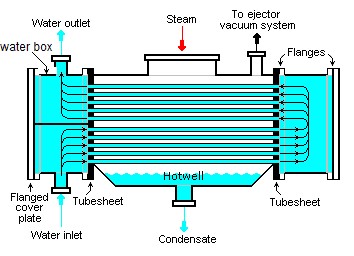

(c) Shell-and-tube type

Shell and tube is the most common type of condenser in large chemical processing plants. In this type of condenser number of straight water tubes are enclosed a large cylindrical shell. The shell may be with or without fins. The common materials for shell are steel and copper. In ammonia refrigerating system steel tube is used because ammonia corrodes the copper. The water tubes are extended to the groove of tube sheet to achieve vapour tight fit. Intermediate support is provided to avoid bending of water tube. The hot refrigerant enters the shell at top. Refrigerant reject heat to the water when it contacts with water tubes. Finally, the condensed refrigerant drops to the bottom of shell.

-

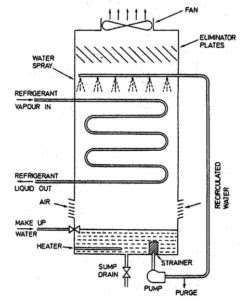

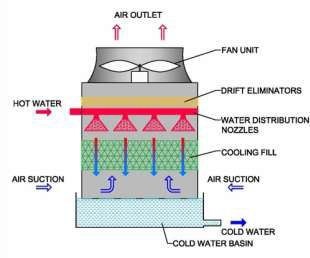

Evaporative condensers

It uses both water and air for cooling of the refrigerant. In this system the water is pumped from sump to spray header and sprayed through nozzles over the condenser coils. The heat transfers from the refrigerant to the water droplets through the tube walls. A fan also used at the top of the condenser which draws the surrounding air from the bottom of the condenser. The air causes water droplets on the surface of the coil evaporates and absorbs latent heat of evaporation from the remaining water to cool it. In this way the refrigerant rejects its latent heat and condenses into liquid. The cold water drops down is collected at the sump where it is re- circulated. The eliminator is provided above the spray header to stop the water particle escaping with air.

- Comparison between water cooled and air cooled condenser

| Water cooled condenser | Air cooled condenser | ||

| Complicated construction | Simple construction | ||

| Maintenance cost high | Maintenance cost low | ||

| Piping arrangement required water | to | carry | No requirement of piping arrangement |

| High fouling effect | Low fouling effect as no corrosion is there | ||

| Heat transfer capacity high | Heat transfer capacity low |

| No fan noise | Forced convection air condenser fan noise is there |

| Even distribution of water on condensing surface | Distribution of air in condenser is not uniform |

| Used for large capacity plant | Used for low capacity plant |

*Fouling factor: The water used in water cooled condenser contains minerals and foreign material which deposits on the tubes. These are called water fouling. This insulates the tube causing reduction in heat transfer rate and water flow rate.

- Heat Rejection factor: it is the ratio of load on condenser to refrigeration HRF=Qc/RE

Where Qc= RE+ work done at compressor HRF=1+(W/RE) =1+(1/COP)

Cooling tower and spray ponds

-

- A cooling tower is enclosed tower like structure through which atmospheric air circulates to cool warm water by direct contact

- A spray pond consists of nozzle and piping arrangement placed over a pond or reservoir

Cooling towers are divided into two main groups: natural draft cooling towers and mechanical draft cooling towers.

Natural draft cooling towers

- Natural Draft Atmospheric Spray Towers: This tower should be located in open space or on the roof of the building where the movement of air is Hot water that needs cooling in the natural draft cooling tower is pumped in via the hot water inlet. The inlet is connected to nozzles that spray the water which provides a large surface area for heat transfer. At the bottom of the tower, the structure is open to draw in fresh air, which then flows upward and allows for direct-contact heat transfer between the warm water and the air. The hot water releases heat after coming into direct contact with the fresh air, and some of the hot water is evaporated. Cold water is collected at the bottom of the tower. The warm and moist air is discharged from the top of the tower into the atmosphere.

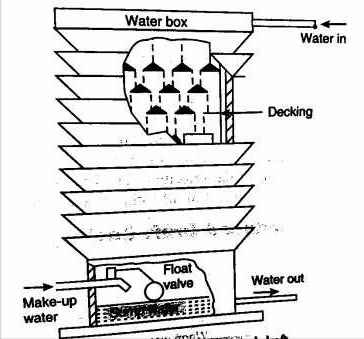

- Natural Draft Atmospheric splash deck type Towers: It is similar to the atmospheric spray tower except that water-distributing troughs are used, which helps to break the water into small The object of the decks is to provide additional evaporation area. It gives 20–30% greater efficiency than the atmospheric spray tower for the same size and for the same quantity of water flow. The water splashes on the decking from the holes of the bottom of the water box placed in top of the tower. The decking helps to break the water into small droplets and slow down the fall of water to the bottom.

Mechanical draft cooling towers

It is similar to Natural draft cooling towers except the fan is used to force the air through them. It uses either propeller or centrifugal fans. This type of towers generally is smaller in size and increased cooling capacity than natural draft cooling towers. However, it requires additional operating cost and power requirement as fan is used.

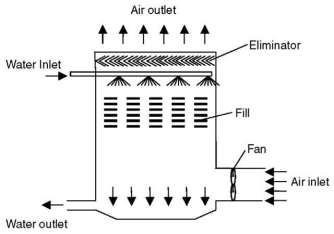

- Forced draft cooling tower: In the forced draft cooling towers the blower type fans are mounted on the lower side of the The warm water from the condenser is sprayed through nozzle. The air is forced upward by the fan presented at the bottom of the tower. The cooling of the water takes place by means of heat transfer and evaporation.

- Induced draft towers: In induced draft towers the fans are located at the discharge (at the top) and pull the air through the Air enters the sides of the tower at low velocity through large openings and passes through the fill, whereas the hot humid air is exhausted to the atmosphere through the ventilator.

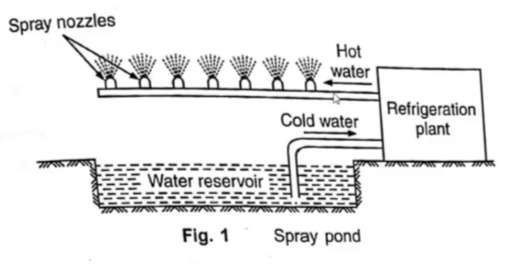

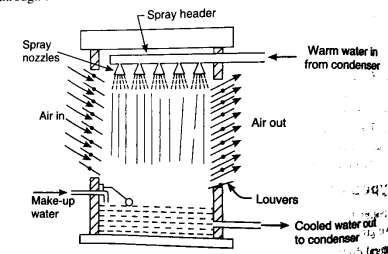

- Spray pond: Ponds are located on the ground or on the treated The water intake from the pond to the condenser is done by using some mechanical pump. The hot water coming out from the condenser is sprayed through the nozzle as fine droplets into the atmospheric air. It is thus cooled and collected at the pond for recirculation.