The basic functions of an expansion device used in refrigeration systems are to:

- Reduce pressure from condenser pressure to evaporator pressure,

- Regulate the refrigerant flow from the high-pressure liquid line into the evaporator at a rate equal to the evaporation rate in the evaporator

- It controls the flow of refrigerant according to the flow of evaporator

Types of expansion devices

- Capillary tube

- Hand operated expansion valve

- Automatic or constant pressure expansion valve

- Thermostatic expansion valve

- Low side float valve

- High side float valve

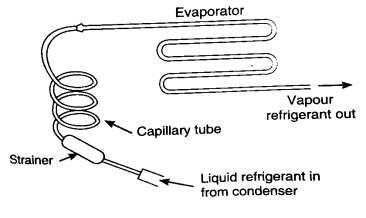

Capillary tube

A capillary tube is a long, narrow tube of constant diameter. Typical tube diameters of refrigerant capillary tubes range from 0.5 mm to 3 mm and the length ranges from 1.0 m to 6 m.

Figure. Capillary tube

The pressure reduction in a capillary tube occurs due to the following two factors:

- When refrigerant enters into the capillary tube, due to frictional resistance offered by tube walls, its pressure drops. Frictional resistance is directly proportional to length and inversely proportional to diameter. So small diameter and longer tube produces greater pressure drop.

- The liquid refrigerant flashes (evaporates) into mixture of liquid and vapour as its pressure reduces. The density of vapour is less than that of the liquid. Hence, the average density of refrigerant decreases as it flows in the tube. The increase in velocity or acceleration of the refrigerant also requires pressure drop.

Several combinations of length and bore are available for the same mass flow rate and pressure drop. However, once a capillary tube of some diameter and length has been installed in a refrigeration system, the mass flow rate through it will vary in such a manner that the total pressure drop through it matches with the pressure difference between condenser and the evaporator. Its mass flow rate is totally dependent upon the pressure difference across it; it cannot adjust itself to variation of load effectively.

Advantages

- Low cost

- When compressor stops, the refrigerant continues to flow to the evaporator and equalise the pressure between high side and low side of This decreases the starting load on compressor. Thus, a low starting motor (low cost) can be used to drive the compressor.

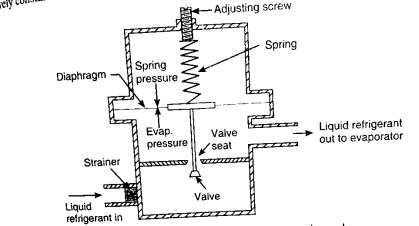

Automatic Expansion valve

Also known as a constant pressure expansion valve – maintain a constant pressure regardless the load on the evaporator. Used with dry expansion evaporators where load is relatively constant. This valve maintains a constant pressure throughout the varying load on the evaporator controlling the quantity of refrigerant flowing into Evaporator.

Figure. Automatic Expansion valve

- It is a diaphragm operated valve with the evaporator pressure acting on the lower side of the diaphragm and atmospheric pressure plus adjustable spring pressure acting on the upper

- As the compressor operates to remove the gas from the evaporator, it reduces the pressure in the evaporator and under the In this case, the adjusting spring pressure pushes the diaphragm down and opens the valve.

- This allows more liquid refrigerant to enter into the evaporator and thus increasing the evaporator pressure till the desired evaporator pressure is

- On the other hand, if the evaporator pressure rises, the diaphragm moves upward, reduces the opening of valve and flow of refrigerant to the

- This decrease of flow of refrigerant lowers the evaporator pressure till the desired evaporator pressure reached

- When the compressor stops, the liquid refrigerant continues to flow into the evaporator and increases the pressure in the This increase in pressure causes diaphragm to move upward and valve got closed. It remains closed until the compressor starts again.

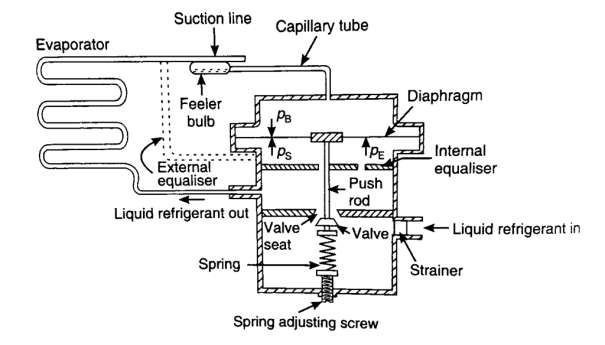

Thermostatic expansion valve

A thermostatic expansion valve is a throttling device which works automatically, maintaining proper and correct liquid flow.

Function of thermostatic expansion valve

- Reduces pressure of liquid refrigerant

- Keeps evaporator active

- Modulates the flow of liquid to the evaporator according to the load requirement of the evaporator

Parts of thermostatic expansion valve

- Needle valve and a seat

- Diaphragm

- Spring and adjusting screw

- Feeler or thermal bulb

The feeler bulb is installed at the suction line, thus, it will be at same temperature as the refrigerant at that point. Any changes in temperature at the feeler bulb, it will change the pressure in the feeler bulb. Under normal condition, the feeler bulb pressure is balanced by the spring pressure and evaporator pressure acting at the bottom the diaphragm. The force tending to open the valve depends upon the feeler bulb pressure. The force tending to close the valve depends upon the spring pressure and evaporator pressure.

When the load on the evaporator increases, it causes liquid refrigerant to boil faster. The temperature of the feeler bulb increases due to the early vaporisation of refrigerant. This increases the feeler bulb pressure. Thus, the diaphragm moves downward and opens the valve. More quantity of liquid refrigerant is now entered into the evaporator.

This will continue when the pressure reaches the equilibrium position. On the other hand when the load decreases, less liquid refrigerant evaporates. The excess liquid refrigerant flows towards the outlet which cools the feeler tube. The feeler bulb pressure decreases due to decrease in temperature. This moves the diaphragm upward and reduces the opening of valve. In this way, the flow of liquid refrigerant to the evaporator decreases. This continues till evaporator pressure and spring maintain equilibrium with feeler bulb pressure.

Figure. Thermostatic Expansion valve

There are two main types of thermal expansion valves: internally or externally equalized. The difference between externally and internally equalized valves is how the evaporator pressure affects the position of the needle. In internally equalized valves, the evaporator pressure against the diaphragm is the pressure at the inlet of the evaporator, whereas in externally equalized valves, the evaporator pressure against the diaphragm is the pressure at the outlet of the evaporator. In internally equalized valves, a hole is drilled in the valve body to transmit the pressure.

The standard thermostatic expansion valve works well on evaporators having low pressure drop. If the pressure drop is high (above 0.14 bar), then, the pressure at the outlet of the evaporator will be less by the amount equal to the pressure drop. In such case, feeler bulb pressure should rise to maintain equilibrium with inlet evaporator pressure and spring pressure. The rise in feeler bulb pressure increases the temperature and the degree of superheat. Thus, the flow of refrigerant to the evaporator reduces. In externally equalized valves, the pressure at the bottom of the diaphragm is equal to outlet evaporator pressure. Thus, the dis-advantages of evaporator pressure drop are overcome. In this case, a small diameter equalizer tube connects the diaphragm with the evaporator outlet.