The evaporator works the opposite of the condenser, here refrigerant liquid is converted to gas, absorbing heat from the air in the compartment. This causes the refrigerant to absorb heat from the warm air and reach its low boiling point rapidly. The refrigerant then vaporizes, absorbing the maximum amount of heat.

While the refrigerant is changing the phase from Liquid to vapor in the evaporator, it absorbs heat from the space/ substance kept in space to be cooled. Evaporator is kept between the Expansion valve and the Compressor.

Principle of working of an evaporator

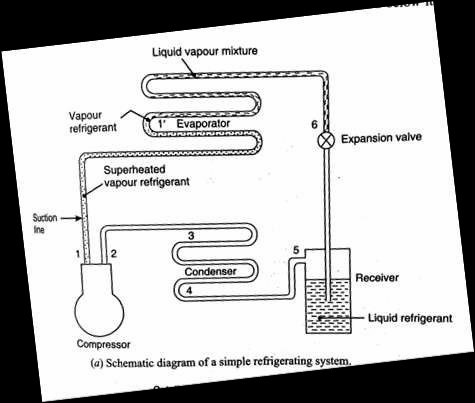

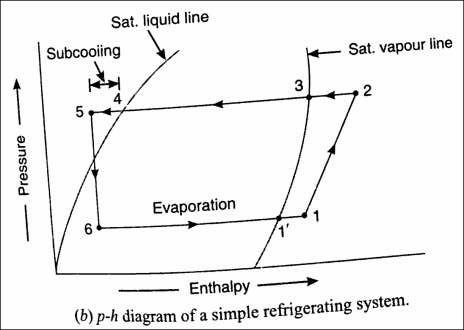

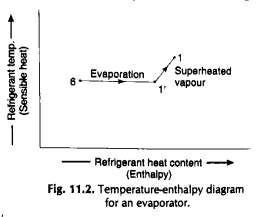

The liquid refrigerant from the Expansion valve with low temperature and pressure enters into the Evaporator (point 6). As the liquid refrigerant passes through evaporator coil, it absorbs the heat from the evaporator coil walls and from the medium to be cooled. Due to this, the liquid refrigerant continues to boil and evaporate. Finally at point 1’, all refrigerants are evaporated and only vapour refrigerant is present in the evaporator coil. Here liquid refrigerant absorbs the latent heat. Since, the vapour refrigerant available is still colder, it keeps absorbing heat (sensible heat) and becomes super heated prior to entering to the compressor suction line (point 1).

The temperature of refrigerant remains constant during evaporation process with steady increase in enthalpy. Here, latent heat is absorbed by the refrigerant and it is converted into vapour from liquid at constant temperature (6-1’). After all liquid refrigerants are evaporated, sensible heating of the refrigerant vapour is performed which increases both temperature and enthalpy and makes the vapour superheated (1’-1).

Types of Evaporator

- According to types of construction

- Bare tube coil evaporator

- Finned tube evaporator

- Plate evaporator

- Shell and tube evaporator

- Shell and coil evaporator

- Tube-in-tube evaporator

- According to mode of heat transfer

- Natural convection evaporator

- Forced convection evaporator

- According to operating conditions

- Frosting evaporator

- Non-frosting evaporator

- De-frosting evaporator

- According to manner in which liquid refrigerant is fed

- Flooded evaporator

- Dry expansion evaporator

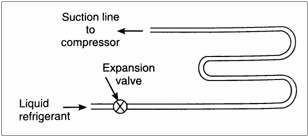

Bare tube coil evaporator

These evaporators are usually constructed of either steel pipe or copper tubings. Copper tubing is used in small evaporators where Freon is used as refrigerant where as steel pipes are used where ammonia is used. This type of evaporator is also called prime-surface evaporator. The bare tube coil evaporators are extensively used in household refrigerators because they are easier to keep clean. Its use is limited to applications where the box temperatures are under 0°C and in liquid cooling, because the accumulation of ice or frost on these evaporators has less effect on heat transfer than on those equipped with fins.

These types of evaporators offer relatively little surface contact area as compared to other types of coil. The amount of surface area may be increased by increasing the length of tubes. But, there is a limitation in extension of length as too long tubes results in vaporise the liquid refrigerant completely earlier which leads to excess superheat. This also results in greater pressure drop between inlet and outlet of evaporator. Proper selection of tube diameter is also crucial. Too large diameter tube results in decrease in refrigerant velocity, rise in refrigerant volume in relation to the surface area of the tube. This results in incomplete vaporisation of refrigerant. Thus, liquid refrigerant may enter into the compressor and damage it. If the diameter is too small, the pressure drop will be too high and reduce the system efficiency.

Fig. Bare tube coil evaporator

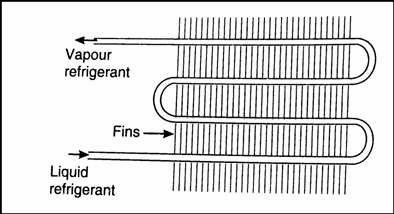

Finned tube evaporator

Finned coils are bare –tube coils upon which metal plates or fins have been installed. The fins increase the surface area of evaporator which means increased heat transfer and capacity. The size and spacing of fins depends upon the type of application. The metal fins are constructed of thin sheets of metal having good thermal conductivity. These evaporators are designed for air conditioning applications where the refrigerator temperature is above 0°C. A finned coil should not be allowed to frost as accumulation of frost between the fins reduces the heat transfer rate. Because of the rapid heat transfer of the finned evaporator, it will defrost itself on the off cycle.

Fig. Finned tube evaporator

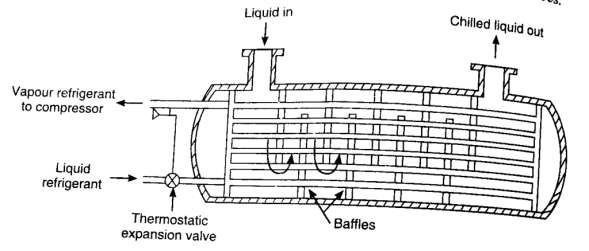

Shell and tube evaporator

The shell and tube types of evaporators are used in the large refrigeration and central air conditioning systems. The evaporators in these systems are commonly known as the chillers. The chillers comprise of large number of the tubes that are inserted inside the drum or the shell. Depending on the direction of the flow of the refrigerant in the shell and tube type of chillers, they are classified into two types: dry expansion type and flooded type of chillers. In dry expansion type, the refrigerant flows through the tubes while in flooded type the refrigerant is in the shell. A pump circulates the chilled water or brine. Dry expansion type uses fins inside the tubes while flooded type uses fins outside the tube. Dry expansion type evaporators are used for small and medium capacity refrigeration plants with capacity ranging from 2 TR to 350 TR. The flooded type evaporators are available in larger capacities ranging from 10 TR to thousands of TR. These evaporators are usually used to chill water or brine.

A flooded type of shell and tube type liquid chiller where the liquid (usually brine or water) to be chilled flows through the tubes and refrigerant circulates around the tube. The refrigerant is fed through a float valve, which maintains a constant level of liquid refrigerant in the shell.

In Dry expansion type Shell-and-Tube Evaporator, refrigerant flows through the tubes and water flow through the shell. The liquid to be chilled flows through the shell around the baffles. The presence of baffles turns the flow around creating some turbulence thereby increasing the heat transfer coefficient.

Fig. Dry expansion Shell and tube evaporator