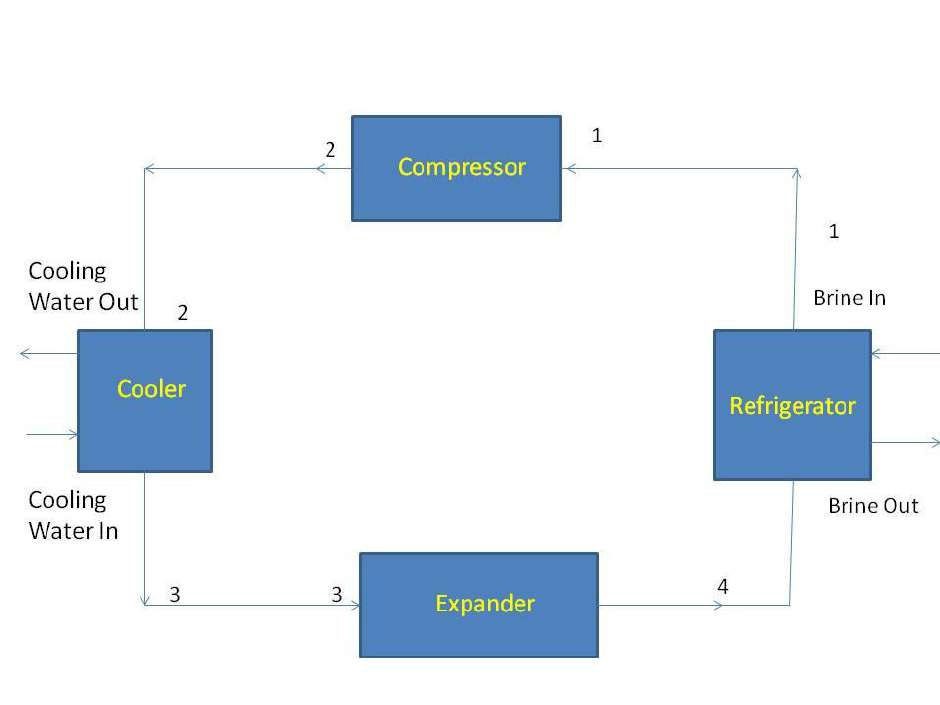

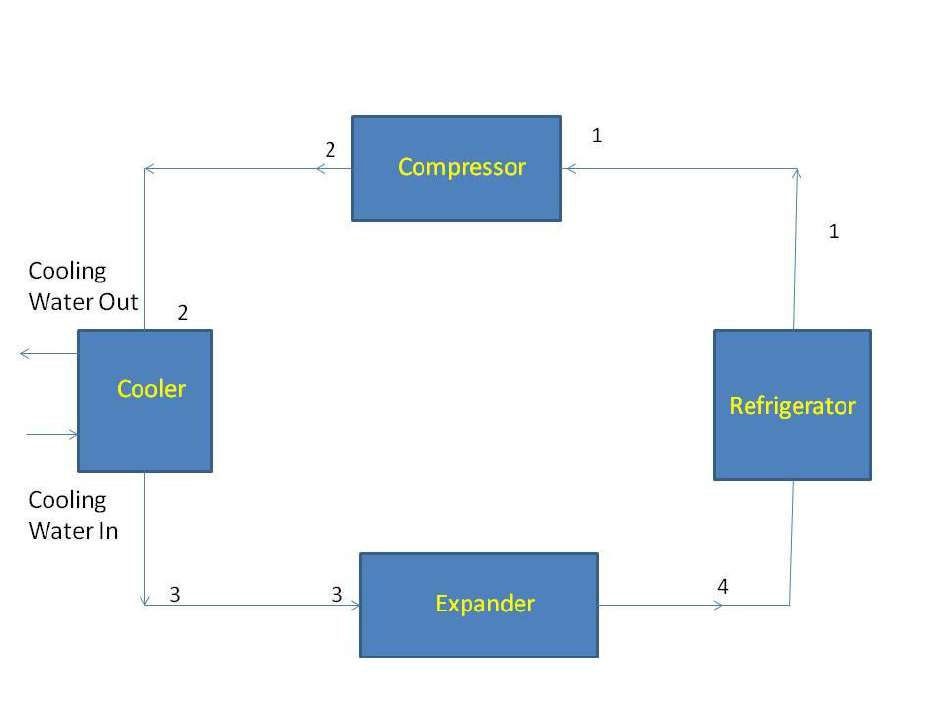

In an air refrigeration cycle, the air is used as a refrigerant. The basic elements of an air cycle refrigeration system are the compressor, the cooler or heat exchanger, the expander and the refrigerator.

Units of Refrigeration

The practical unit of refrigeration is One tonne (1000 kg )of ice from and 00 in 24 hours.

expressed in terms of “tonne of refrigeration’ (briefly written as TR). A tonne of refrigeration is defined as the amount of refrigeration effect produced by the uniform melting of one tonne (1000kg) of ice from and at OC in 24 hour.

Since the latent heat of ice is 335 kJ/kg, therefore one one of refrigeration= 1 TR= 1000×335 kJ/ in 24 hours= (1000×335)/ (24×60) =232.6 kJ/min

In actual practice, one tonne of refrigeration is equivalent to 210 kJ/min or 3.5Kw (3.5 kJ/s)

Coefficient of performance

The coefficient of performance (C.O.P) is the is the ratio of heat extracted in the refrigerator to the work done on the refrigerant. It is also known as theoretical coefficient of performance. Mathematically,

Theoretical C.OP. = Q/W

where Q=Amount of heat extracted in the refrigerator (of the amount of refrigeration produced, or the capacity of a refrigerator and

W = Amount of work done.

- For per unit mass, C.O.P=q/w

Find the C.O.P. of a refrigeration system if the work input is 80kJ/kg and refrigeration effect produced is 160 kJ/kg of refrigerant flowing

Solution. Given: w = 80 kJ/kg : q = 160 kJ/kg

C.O.P. = q/w = 160/80= 2

Air cycle refrigeration is one of the earliest methods used for cooling. The key features of this method is that, the refrigerant air remain gaseous state throughout the refrigeration cycle. Based on the operation, the air refrigeration system can be classified into

- Open air refrigeration cycle

- Closed refrigeration cycle

Open air refrigeration cycle

In an open refrigeration system, the air is directly passed over the space is to be cooled, and allowed to circulate through the cooler. The pressure of open refrigeration cycle is limited to the atmospheric pressure. A simple diagram of the open-air Refrigeration system is given below.

Advantages and application

- It eliminates the need of a heat

- It is used in aircraft because it helps to achieve cabin pressurization and air conditioning at once

Disadvantages

One of the disadvantages of this system is that its large size. The air supplied to the refrigeration system is at atmospheric pressure, so the volume of air handled by the system is large. Thus the size of compressor and expander also should be large. Another disadvantage of the open cycle system is that the moisture is regularly carried away by the circulating air, this leads to the formation of frost at the end of the expansion process and clogs the line, and hence a use of dryer is preferable to the open air refrigeration system.

Closed refrigeration system / Dense air refrigeration cycle

In closed or dense air refrigeration cycle, air refrigerant is contained within pipes and component part of the system at all time. The circulated air does not have to direct contact with the space to be cooled. The air is used to cool another fluid (brine), and this fluid is circulated into the space to be cooled. So the disadvantages listed in open air refrigeration can be eliminated. The advantages of closed air refrigeration system are

Advantages

- The suction to the compressor may be at high pressure, therefore the volume of air handled by the compressor and expander is low when compared to an open Hence the size of compressor and expander is small compared to the open air system.

- The chance of freezing of moister and choke the valve is

- In this system, higher coefficient of performance can be achieved by reducing operating pressure

Bell Coleman Cycle

Bell Coleman Cycle also known as a Reversed Brayton Cycle or the Joule cycle. The Bell Coleman Cycle is a refrigeration cycle where the working fluid is air which is compressed and expanded but do not change state. … In this cycle, the process of compression and expansion of gas is isentropic and heat absorption and rejection of heat takes place at constant pressure i.e isobaric process

Closed Bell Coleman Air Cycle

Open Bell Coleman Air Cycle

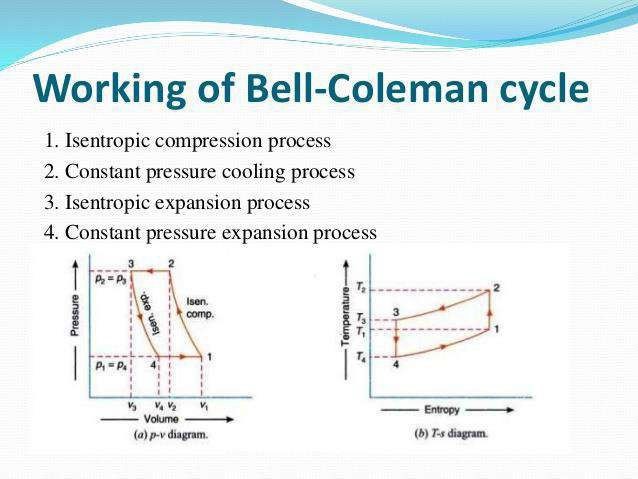

P-V and T-S diagram of bell coleman refrigerator. Here P1, V1, T1, S1 represents the pressure, volume, temperature, entropy of air respectively at point 1. And so on. It represents the corresponding condition of air when it passed through the component.

1-2 Isentropic Compression: The Cold air from the refrigerator is brought into the compressor and compressed isentropically. During this procedure, the pressure increments from P1 to P2. The specific volume decreases from v1 to v2 and the temperature increments from T1 to T2. During this procedure

Entropy ‘s’ stays steady (s1=s2). No heat is absorbed

or rejected by the air.

2-3 Constant Pressure Cooling Process: The warm air from the compressor is then passed into the cooler where it is cooled at constant pressure, reducing the temperature from T3 to T2. The specific Volume reduces from v2 to v3.

Heat rejected by the air: Qr = Cp (T2 — T3 )

3-4 Isentropic Expansion: Air from the cooler is presently brought into the expander and is extended isentropically. The pressure of the air stays steady during this process. Specific volume changes from v3 to v4 and the temperature decreses from T3 to T4. No heat transfer takes place.

4-1 Constant Pressure expansion process: The cold air from the expander is then passed into

the refrigerator and extended at a constant pressure. The temperature of the air increases from T4 to T1. The specific volume of the air changes from v4 to v1.

Heat absorbed by the air: Qa = Cp( T1 — T4)

Work done during the cycle per kg of air = Heat rejected — Heat absorbed

= Cp(T2 — T3 ) — Cp( T1 — T4)

- during the cycle per kg of air = Heat absorbed / work done

= Cp( T1 — T4 ) / Cp(T2 — T3 ) — Cp( T1 — T4)

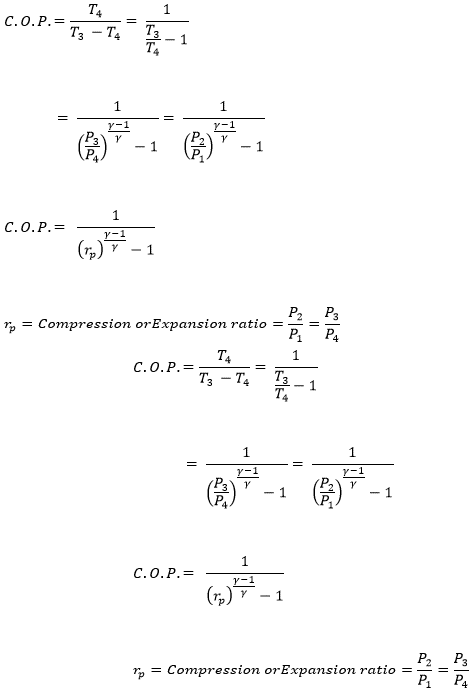

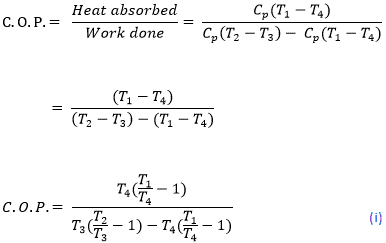

Equation of Coefficient of performance (COP) of Bell Coleman cycle:

Heat absorbed during cycle per kg of air q4-1 = Cp(T1-T4) Heat rejected during cycle per kg of air q2-3 = Cp(T2-T3)

Then the work done per kg of air during the cycle is = Heat rejected – Heat absorbed

= Cp(T2-T3) – Cp(T1-T4)

Coefficient of performance;

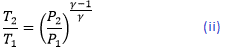

For isentropic compression process 1-2

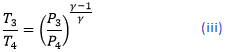

For isentropic expansion process 3-4

Since, P2 = P3 and P1 = P4, therefore from equation (ii) and (iii) Substitute equation (iv) in (i)